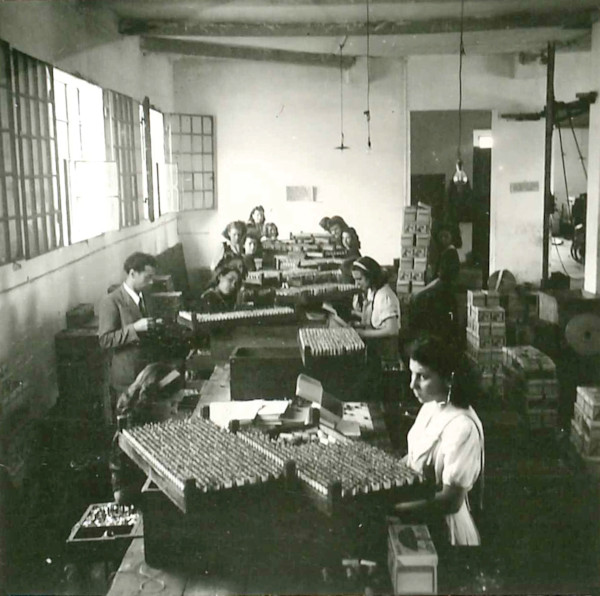

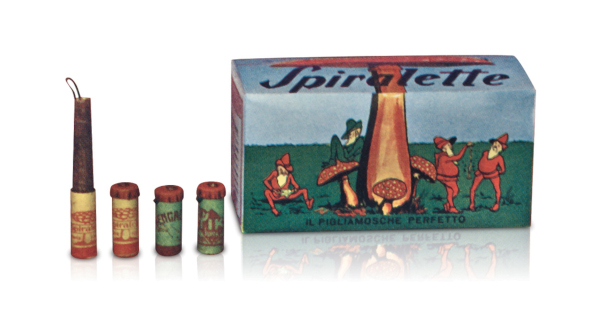

The year 2019 has been dedicated to the storytelling of our 100 years of history: an intense year full of memories, emotions, embraces, smiles and celebrations...

The year 2019 has been dedicated to the storytelling of our 100 years of history.

An intense year full of memories, emotions, embraces, smiles and celebrations.

A global event in honour of a company that can count over 5,000 employees dotted all over the world, creating that unique and special mix of cultures, colours and values that will enable us to live the next 100 years to the full.